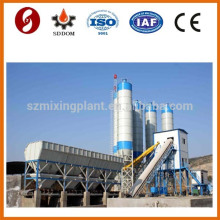

50m3 / h Central de betão portátil à venda

Informação básica

Modelo: YHZS50

Descrição do produto

1.Capacity: 50t / h

2. Controle elétrico avançado

3.Reliable serviço pós-venda

50m3 / h Usina Portátil de Betão

YHZS série de betão celular fábrica de mistura é um novo tipo de betão móvel trailerable mistura fábrica.

Sua estrutura é única com novidade para combinar várias funções de coleta, pesagem, mistura e transporte em uma unidade de reboque para uma excelente mobilidade.

É capaz de misturar a dureza seca, a dureza meio seca, o concreto plástico.

1. Misturador obrigatório de dois eixos

2. Dobrar a máquina de carga de três hopper

3. Janelas multi-idioma que operam

4. elevado automático, alta produtividade, alta flexibilidade

O parâmetro da YHZS50 Portable Betão Batching Plant

Item |

Parts |

Specification |

1 |

The mixing system |

1.Model number: YJS1000 2. Type: twin-shafts forced type 3. Charging capability 1600 L 4. The discharging capability 1000 L 5. The discharging height: 3.8 m 6. Maximum diameter of aggregate (cobblestone /broken stone) 80/60mm 7. Motor power: 2*22KW 8. Planet Gear Reducer: ZQ650-20.49-Ⅱ 9. The mixing blade and lining board: wear-resisting material 10. The discharging cylinder: SC-80××200-CA-Y 2 units

|

2 |

The aggregate batching and weighing system |

The aggregate batching and weighing system is composed of aggregate bins, the frame, weighing hopper, the aggregate conveyor, sensors and so on. 1. The aggregate batching hopper i. The volume: 7m3*4 ii. The discharging gate: 4 units iii. The cylinder: SCF-80×200-CA-Y, 2 units iv. The cylinder: SCF-80×250-CA-Y, 2 units 2. The weighing hopper i. Volume: 1800L ii. The measuring method: the accumulating measuring iii. The sensors: 2000kg×3 iv. The measuring accuracy: ±2% 3. The belt conveyor ii. The belt dimension: 650mm iii. The belt speed: 2m/s 4. The electric drum i. Model number: TDY75-5.5-1.25-65-40 ii. Power: 5.5kW |

3 |

The hoisting system

|

1. Adopts the high-side belt conveyor with high efficiency 2. The power of the electric driving drum: 15KW

The system introduction The windlass drives the winding drum with the help of reducer. The hopper at the effect of traction steel rope climbs up along the rail. When it reaches a certain height, a pair of rollers at the bottom of the hopper goes into the level turnoff of charging frame. Then the hopper bucket door open automatically discharging the material into the mixer |

4 |

The cement or fly ash weighing system |

The cement or fly ash weighing system is composed of fly ash weighing hopper, pneumatic butterfly valve and sensors 1. The cement or fly ash weighing hopper i. Volume: 600L ii. The weighing hopper: 0~600 kg iii. The weighing accuracy: ±1% 2. The sensors: 500 kg×3 3. The pneumatic butterfly valve: BV1FS250

|

5 |

The water weighing system |

The water weighing system is composed of self –built pool, water pump, water weighing hopper and electromagnetic valve and so on 1. The water supply pump model number: QY40-16-3, motor Power: 3 kW 2. The water feeding ball valve: 671X-10 DN32 3. The weighing scale volume: 400L 4. The sensors: LC-E-V-300kg×3 5. The weighing accuracy: ±1% 6. The water discharging valve: GTD671X-10 DN125 |

6 |

The additive weighing system |

The addictive weighing system is composed of addictive box, addictive scale, water pump, sensors and so on. 1. The mixing addictive pump: GISG25-125: Power: 0.75 kW 2. The three way pneumatic ball valve: Q615F-16P-DN25 3. Addictive scale volume: 25L 4. The addictive box volume: 2m3 5. The weighing accuracy: ±1% 6. The sensor: LC-C-0.1T 7. The pneumatic butterfly valve: D671X-10 DN50 |

7 |

The pneumatic discharging system |

The pneumatic discharging system is composed of air compressor, cylinder, electromagnetic valve and pneumatic components 1. The air compressor: LB150350, 11kW 2. Electromagnetic valve 3. Cylinder 4. The gas source processing components |

8 |

The electric control system |

The electric control system is composed of host computer, display, printer, weighing instrument,telecommunication cable and etc |

9 |

Main Frame Bracket |

It is composed of ladder, platform, guard rail and steel bracket |

10 |

The screw conveyor |

The screw conveyor i. Dimension: 219×9000 ii. Quantity: 1 unit iii. The conveying capacity: 45t/h iv. The motor power: 11 kW |

11 |

Powder silo |

Powder silo i. Dimension:100t, 1 unit(square-type cement silo bin) ii. The dust collector: 1 unit |

12 |

The control room |

The control house 1. Use color sandwich panel with function of heat preservation and heat—insulation 2. The air-conditioner 3. Bracket |

13 |

Towing system |

The whole machine will be installed on a car tray. The buyer just needs a tractor. We will offer the related equipments. |

14 |

The total power and weight |

about 85kW and 30t |

Grupo de Produto : Planta de dosagem de concreto semi-móvel